Responsibility and sustainability

Our work matters. Developing solutions with critical metals has an impact on the planet, we are well aware of that. At Umicore Rechargeable Battery Materials we genuinely believe we can thoroughly answer our clients’ needs and – at the same time – contribute to environmental progress and our society’s future.

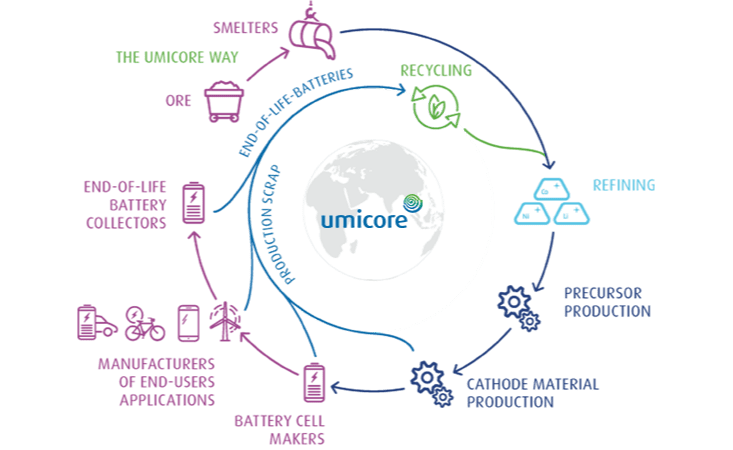

Embracing the circular economy as a future-proof business model, we drive innovation in closed-loop processes. From raw material sourcing to end-of-life battery recycling, we manage the entire chain with an unwavering commitment to quality.

From framework to footprint, we go the extra mile

When resources are scarce, you need a resourceful partner. As resourceful as reliable and responsible. Our business model and strategy honour our purpose to limit carbon emissions and facilitate the sustainable energy transition in mobility. We address acute ethical and environmental concerns with a sense of urgency. Clean power brings a bright future.

Environmental footprint

Life Cycle Assessment

Measuring emissions is not restricted to an electric car’s performance on the road. When we analyse the complete production process, we see cathode materials have a significant impact on the carbon footprint of EV batteries.

By setting up the Life Cycle Assessment, we gained valuable insights and a complete understanding of our products’ CO2 emissions. Our studies and robust research data accurately pinpoint opportunities to reduce these emissions. We are increasingly processing recycled materials and we intensify our investments in renewable energy to power our plants.

Ethical sourcing

Sustainable procurement framework for cobalt

The sourcing of cobalt is not beyond reproach. Umicore was the first company to create a ‘Sustainable Procurement Framework for Cobalt’ (SPFC) to ban unfair practices from our supply chain and, consequently, that of our clients.

This protocol sets specific standards for suppliers worldwide. They are screened and visited for both scheduled and unexpected audits scrutinising environmental stewardship, labour practices, human rights, business integrity and supply chain management. Our SPFC is aligned with the OECD ‘Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas'. Furthermore, the SPFC is annually validated by an independent third party.

The principles for ethical and sustainable sourcing of all other materials have been outlined in our ‘Sustainable Procurement Charter’. Both documents are available in their entirety on our website.

Global Battery Alliance

As a member of the Global Battery Alliance – a public-private platform – we support the mission to establish a battery value chain that is sustainable on a social, environmental and economical level.