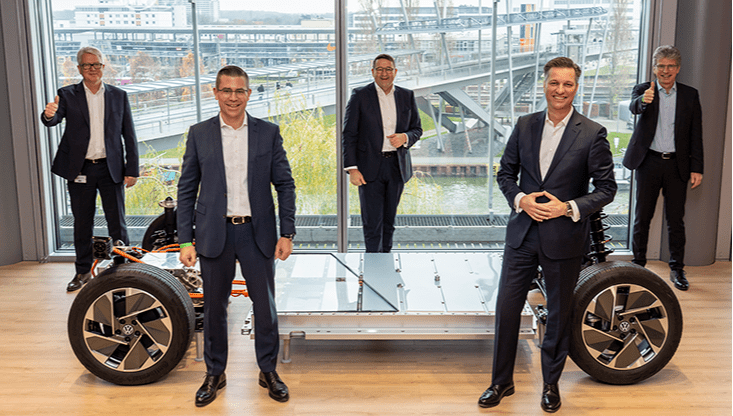

Umicore and Volkswagen AG to create European EV battery materials Joint Venture

Umicore and Volkswagen AG plan to establish a joint venture to build up precursor and cathode material production capacities in Europe to supply Volkswagen AG’s European battery cell production, making a considerable contribution to the region’s transition towards cleaner mobility.

This partnership will be the first of its kind in the European automotive market. It will help achieve the ambitions of the European Green Deal, including the establishment of a sustainable battery supply chain, and is a strong signal for the ongoing roll-out of innovative battery cell technologies and capabilities in the region.

The intention is to gradually ramp up the JV’s precursor and cathode material production capacity. This would start in 2025 with an initial annual production of 20 GWh for Volkswagen AG’s plant in Salzgitter, Germany, and should grow to an annual production capacity of up to 160 GWh by the end of the decade. This compares to an annual production capacity capable of powering about 2.2 million full electric vehicles (EVs).

At the same time, next to the intended JV, Umicore will continue to steadfastly develop its technological and production capabilities to serve other customers and regions.

“As a leader in clean mobility materials, we are committed to support our automotive and battery-cell customers with their electrification strategies.

We are very pleased to partner with Volkswagen in this unique joint venture and will bring in our long-standing and proven expertise in battery materials, as well as our strong commitment and solutions to today’s sustainability challenges.

The complementarity of our extensive technology, innovation and industrial knowhow, and shared sustainability convictions will provide a strong framework for the JV and will give us a considerable first-mover advantage.”

Mathias Miedreich, CEO of Umicore

Thomas Schmall, Member of the Board of Management of Volkswagen Group for Technology and CEO of Volkswagen Group Components: “Volkswagen is implementing its battery strategy very consistently and at a high pace. The Volkswagen unified cell must be at the forefront of performance, costs and sustainability right from the start. Teaming up with Umicore enables us to establish a state-of-the-art supply chain in Europe as we share common values such as responsible sourcing of raw materials, as well as closed-loop thinking.”

The partnership’s significant scale will provide secure and cost-competitive supplies of innovative, sustainably sourced and tailored high-performance cathode materials for Volkswagen AG’s ambitious unified cell strategy. It provides Umicore secured access to an important part of the European demand for EV cathode materials, which will unlock significant economies of scale and represents a major leap forward in the further roll-out of its strategy to be a global leader in clean mobility materials.

In the context of the JV, Umicore and Volkswagen AG will furthermore collaborate on the sustainable and responsible sourcing of raw materials, which is a strong area of expertise of Umicore. Both parties aim to include at a later stage, elements of refining and battery recycling into the scope of the JV.

The planned JV is subject to final agreements and customary conditions, including regulatory approvals.

Short-term earnings in battery materials hampered by lower volumes in combination with higher fixed costs related to recent and ongoing expansions

The JV’s portfolio offering will cover next-generation technologies, including a very large portion of high-nickel chemistries. The latter have become faster than anticipated the car industry’s preferred solution to enable higher energy density and longer driving ranges and this is consequently significantly impacting demand for mid-nickel chemistries. Umicore successfully fast-tracked innovation on the next generation higher nickel product and process capabilities and now offers industry-leading high nickel cathode material technology, as also witnessed by today’s announcement.

In the short-term, Umicore is still largely exposed to mid-nickel NMC platforms. Customer demand projections for certain of these qualified mid-nickel platforms are being scaled back to their minimum offtake commitments, resulting in lower volume forecasts for 2022 and 2023, beyond the negative volume impacts from semiconductor shortages. Consequently, Umicore now expects growth in its cathode material sales volumes in 2022 and 2023 to be less than previously anticipated and to be below the anticipated global market growth. These scaled-down short-term volume expectations, together with the need to increase fixed costs to prepare for the expected steep mid-term growth, such as higher R&D expenses and costs related to the recent and ongoing expansions, are likely to result in lower-than-expected earnings growth in Rechargeable Battery Materials in 2022 and 2023. Hence, assuming that Cobalt & Specialty Materials will not repeat the exceptionally strong 2021 performance, the earnings of the Energy & Surface Technologies segment are not expected to show a significant uplift over that period.

Strong mid-term earnings growth comforted

Umicore’s innovation pipeline and strong track record in cathode material technologies, alongside with its flexible production system have allowed to act with agility to the rapidly evolving customer voice. The intention to set up this JV with Volkswagen AG contributes further strength to the Group’s competitive positioning. Its strong technology roadmap, synced with customers’ requirements, puts Umicore in a unique position to disproportionally benefit in the mid-term from the extremely high anticipated growth in EV battery materials. This will significantly boost operating leverage through economies of scale and will allow Umicore to achieve attractive margins and returns in its fast-growing battery materials activity.